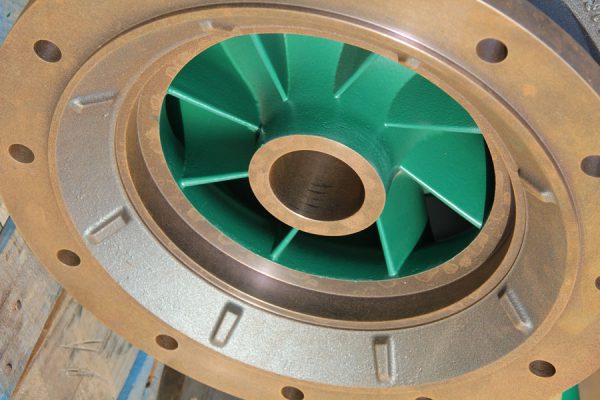

Powder coating is a safe, dry finishing process used to create a protective finish that is used on metals and aluminum products. This process creates a hard finish that is tougher than conventional paint that results in a durable, rust-free, chip resistant, and long lasting finish.

Powder coating is a type of dry coating that looks like paint but is applied as a free flowing dry powder. It is the safe alternative to the chromium plating process which is considered hazardous and requires permits and expensive precautionary measures.

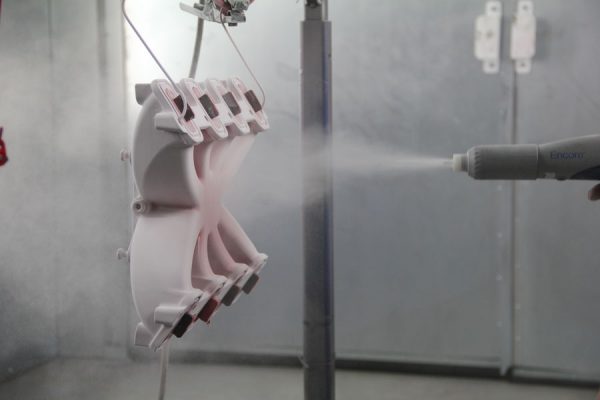

The powder coating product is made of finely ground particles of pigment and resin which makes it low in toxicity and has low flammability. Powder is applied using a special electrostatic spray gun which charges the particles with static electricity and then sprayed onto metal surfaces that have been grounded. The resulting magnetic attraction causes the particles to adhere to the surfaces.

The metal items are then heated to 350 – 450 degrees Fahrenheit. The powder melts and adheres to the surface creating a uniform film and then is cooled to form a very durable finish. When applied properly, this process eliminates the problem of run or drip marks on the finished product.

Environmental Impact

Since powder coating uses no solvents it is a much safer process to the environment. The powder coating process has little impact on the environment since the process emits zero or near zero volatile organic compounds (VOC). The spray booths are easily maintained and cleaned without the use of harmful solvents or paint washes. With the growing need to reduce pollution, powder coating is an ideal process and a safe alternative to the liquid painting processes.

Advantages

There are cost and safety advantages to using powder coating. The complete powder coating process is easier to meet regulations. Since the exhaust from the powder coating ovens is lower and more manageable than exhaust from solvent-based coating, this reduces the energy used to complete the powder coating process.

Powder coatings can produce a much thicker coating. A 1-3 mil. average thickness can be obtained in one powder application coat. The liquid, solvent spray could take two to three coats to obtain this thickness. The additional application increases the processing time and the expense to obtain the necessary finish.

Using the powder coating process, the parts are fully cured when they leave the oven. The total processing time is much shorter, keeping the cost to a minimum and reduce the turn-around time to the customer.

Application

Powder coating started out as a finish for industrial metal products. Now powder coating is an increasingly popular finish for many of our everyday products because it is solvent free. Powder coating gives consumers, businesses and industry and economical, long lasting and durable finish.

Uses for powder coating are:

- lighting fixtures

- car chassis

- wheels

- filing cabinets

- exterior signs

- barbecue grills

- patio furniture

- metal railings or fencing

- park benches

- garden tools

- stainless steel mugs

- hitch covers

- race car frames

- ATV frames

- bicycle frames

- truck accessories

- grill guards

- golf clubs

- exercise equipment

Powder coating can be decorative as well as protective. The coating colors are almost unlimited with high gloss, semi-gloss, matte, metallic and clear finishes available. Special effects are also available such as: glitter, antiquing, veining, holographic, textures and rough pebble finishes.

Contact Us

GIVE US AN OPPORTUNITY TO PROVIDE SOLUTIONS.

Call us Monday-Friday 8:00 a.m. – 5:00 p.m. or use the form to let us know

how we can help you with any coating projects

11617 HWY 87 | LUBBOCK, TX 79423

Fax: 806-722-0015